How Mattresses Are Made: The Basics

Understanding how mattresses are made is critical if you want to know what is under the hood is worth taking a look at. Our site reviews and recommends only a handful of trusted mattress dealers, and customers often write us in an attempt to understand the process involved in creating, designing, and manufacturing a really comfortable mattress.

Think of most mattresses as a sandwich, in which various layers are added from the bottom up to provide comfort and support. Humans have building mattresses the same way for thousands of years.

The outer covering, or encasement, serves the purpose of acting as the mattress “skin”, keeping all of the contents in place and protecting the contents.

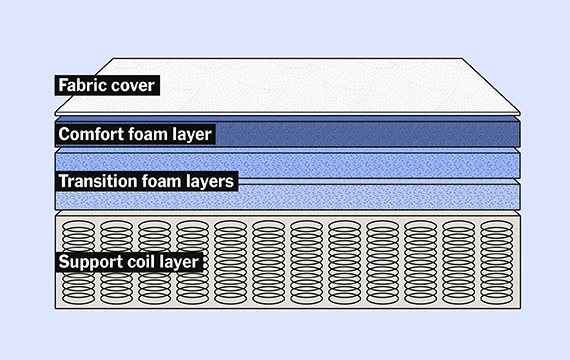

Typically, the underlying section of a mattress is referred to as the “foundation layer” and may be made from foam, an innerspring or pocket coil unit, or from various layers of cotton or other organic materials that adds loft and height to the mattress.

The purpose of this part of the mattress is to provide support for the torso area of your body, to distribute weight, and to provide buoyancy to keep you from sinking or bottoming out.

How Mattresses Are Made: Components Used To Provide Comfort

With a foam mattress, even though they all might have a similar appearance on the outside, the design and the technique of assemble, along with the outer fabric covering, has a tremendous influence on how the mattress feels, whether spongy and soft, firmer and more resilient, cloud-like, offering that “melting” sensation, and on and on.

To build a mattress that will perform over a long period of time without compressing or developing ruts and depressions, takes seasoned experience, knowledge of many different kinds of foams, adhesives, fabrics, and other components.

Designing a mattress has must also factor in how easily it can be shipped to a consumer. Today, many mattresses are either compressed and rolled, vacuum packaged, or even shipped in its original size in a large box. The materials used must be capable of expanding back to its original size.

How mattresses are made, and how the ingredients selected may seem confusing. Is there a kind of cookbook for designing a bed in a box mattress? The answer is yes, basically. Almost all mattresses sold online are either created using all foam, or a mixture of foam and coils. Understanding how they are made offers insight into the kind of comfort and support you can expect.

Want to read an interesting article about the history of mattresses? Check out this link for additional information as well as obscura, like the latin terms for different kinds of mattresses used in ancient Rome.

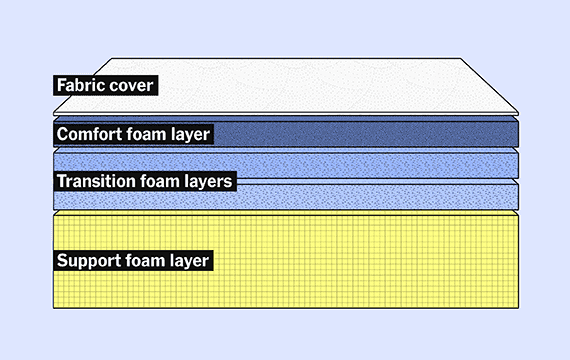

All foam mattresses, including the bed in a box variety typically begin with the selection of a substrate or base layer, which is usually a block of specialized polyurethane foam, generally about 5-6” thick.

Occasionally this foundation or base layer may be made of two pieces laminated together using an adhesive, but in most cases it is one block of foam that is fairly firm.

The firmness is calibrated by a unit of measurement called ILD, which means Indentation Load Deflection, defined as the weight required to depress a cubic foot of the sample material one inch, if a flat surface is place across the top.

So if it takes 32 pounds of pressure across one square foot of area to compress a sample 1 inch, the ILD for that foam material is 32 ILD. Simple enough.

Most consumers have no interest in ILD measurements on a prospective mattress, but if you have back issues or need a firmer mattress option, it’s good fundamental knowledge to have. The difference between a great mattress and a crappy one is important when finding out how mattresses are made.

You can use industry nomenclature to help you make sure you are buying a quality mattress, too, and if you are able to chat with an agent or speak to a sales person about ILD and other metrics, you typically will strike them as more educated than the average consumer, which just might get you a better deal, too.

Say if you are shopping online, you might get into chat with a rep abiout what your specs need to be, or ask them to lay out the ILD’s of their mattress, and then followup with a request for a better deal.

How Mattresses Are Made: Creating A Prototype

When I designed a prototype, I always started with a base of 6” high density polyurethane foam, roughly around 40 ILD, firm, but appropriate for the foundation that all of the other component layers will be stack on top of.

Above that level, generally a designer will insert what is called a transitional layer, though it may be referred to by many proprietary names based on the design, the shape (waffled, waved or zoned areas).

The purpose of this layer is to build height on the mattress, to provide some pushback and cradling for hips and shoulders, and to dampen motion.

Generally, this layer is made using a slightly less dense material, say around 32-36 ILD, and it could be a high density polyurethane foam, which might be what is called “open cell”, meaning that the foam has a significant amount of bubble in its mix, added during the foam mixing process.

Other components like urethane foam (memory foam) type ingredients may be used. In fact, because of it’s pressure relieving ability, memory foam is found in the vast majority of well designed bed in a box mattresses.

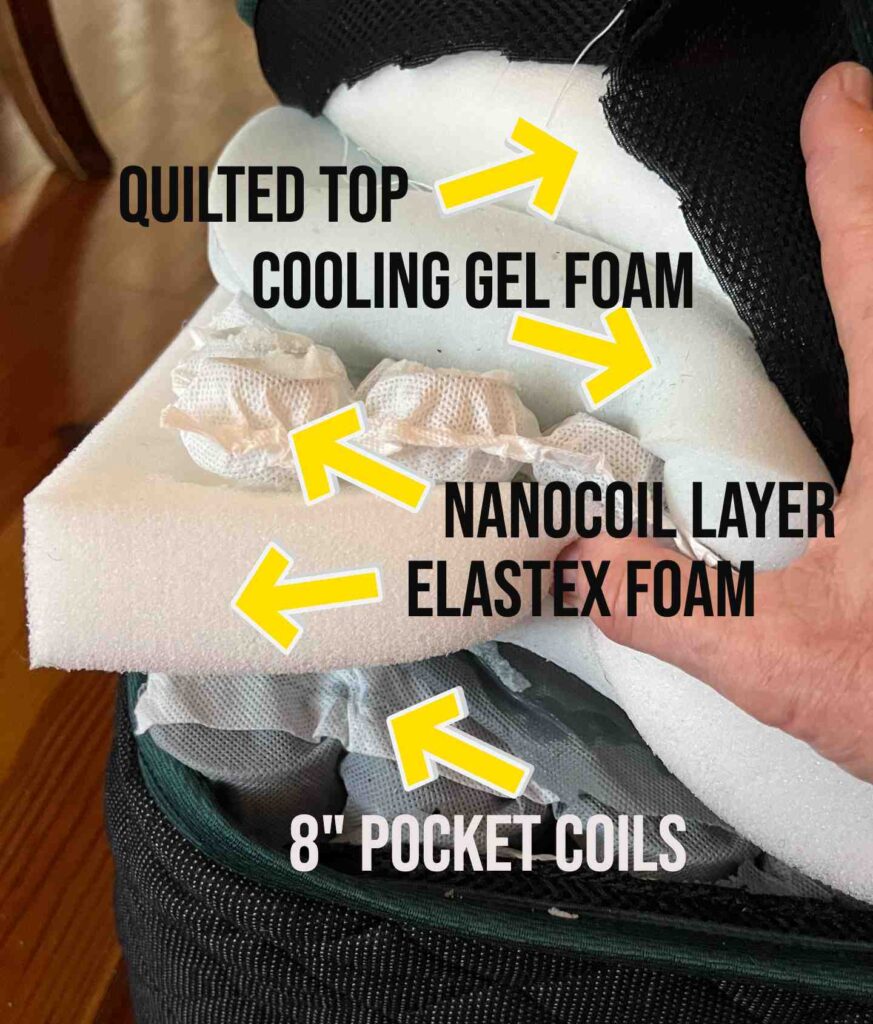

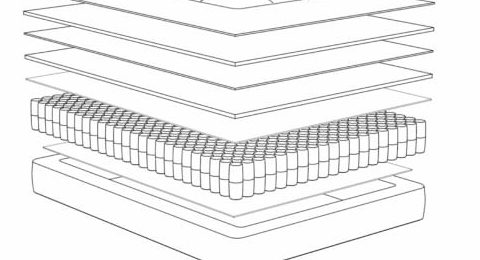

Typically, transition layers are pretty firm, and you don’t really want to see a lot of compression, unless its accommodating heavier areas of the body like hips and shoulders. Also, in the transition are just above the foundation layer, you may also see pocketed coil layers, seen more and more in to hybrid mattresses.

Pocketed coil units are self contained and easily built into bed in a box designs since they handle compression and rolling with ease.

These systems are surrounded by a fabric layer, and the unit might be laminated with an adhesive to the transitional foam later immediately above and below.

A pocketed coil unit not only adds support and helps with spine alignment issues, but it also provided pinpoint support by “mapping” small areas of the body, and reacts to movements, providing support and pushback on heavier areas.

Sitting on the edge of a mattress with a pocketed coil system is more comfortable and beneficial than an all foam mattress, so people who have transferring issues will be able to sit without sinking, making getting up and out of bed a lot easier.

Most pocketed coil units have a variety of coil sizes, and when I have designed various mattress types, I would often choose zoned coil systems that provide firmer and a higher concentration of coils both at the edge perimeter and in certain areas of the mattress insert as well.

A mattress engineer can choose from different degrees of bounciness, firmness, and reaction time, depending upon how the coils are fabricated, which can dramatically alter the feel of the mattress.

This adds to the versatility of the a hybrid mattress with pocketed coil components, too, and more and more online mattress companies are creating these kinds of beds.

Above the transitional layers found in a foam mattress are the final finishing or “comfort layers”.

These layers are designed to establish the finished feel of the mattress, and very often you will find the softer layers of memory foam, latex, waffle style foam, copper or charcoal infused foam, and even gel foams built into this area of the mattress.

How Mattress Are Made: Pieces And Parts Glued Together?

Essentially, a finished mattress that is considered medium of high quality designed for bed in a box applications, will have several thinner layers of laminated memory foam, gel foam, or latex foam included in the comfort layers area.

A will built mattress will be laminated together, piece by piece, using preferably, a water based adhesive, and not a VOC based glue, which contains formaldehyde, heavy metals, and other noxious components.

I recommend always asking what kind of adhesive is being used in any mattress you are considering. The best adhesive, used by experienced and higher end mattress designers, is a water based adhesive called Simalfa.

For the outer textile, or fabric encasement, often referred to as the ticking on a mattress, is typically made using cotton, a blend of polyester and cotton or bamboo, and often will include wool as a natural fire barrier, too.

If a fabricator or mattress engineer has designed mattress using a non-natural fire barrier other than wool, you need to make sure that the material inert. Inert flame retardant fabrics do not leach chemicals, off gas, or interact with foams or other ingredients in a mattress.

As an example, Nest Bedding uses an inert fire barrier material that does not contain any flame retardant chemicals. They use hydrated silica as a primary ingredient in their fire barrier material, which covers the entire mattress. The barrier fabric is woven with inert silica, a naturally occurring element, which also happens to be an active ingredient in toothpaste. In the event of a fire, this barrier melts onto itself and suffocates the oxygen needed for fire to burn.

Regardless of the mattress you choose, you will find a fire certification tag on the end of the mattress which is required by law. In the United States, all mattresses offered for sale to the public must pass stringent and difficult testing which subjects the mattress prototype (actually six each of them) to an open flame applied directly to the material.

The outer fabric encasement of the mattress provides the finished look of the bed, and often influences consumers decision to purchase. Often, by adding quilted layers and tufting (the buttons or flourishes that you see sewn into the top of a mattress) actually adds a layer of tactile softness which foam materials cannot produce.

These built in comforters on the top of the mattress offer a soft, cloud like feel, and gives a sense of immersion and a “cuddling” sensation, which many consumers seek out.

For those who like a firmer mattress underneath and want proper spine alignment and support, having a softer finished layer and top often delivers the best chemistry for a back or belly sleeper.

I used a lot of bamboo fabric in many of my designs, because it breathes effectively, allowing for passive ventilation, which keeps you cool. There are a lot of “technical fabrics” available too, such as Cool-Max and Tencil, which are specialized fibers that wick away moisture and create an evaporative effect, almost like an air conditioner built into your bed.

A couple pointers on outer coverings…ask to see if you can opt for a zippered covering. If anything were to happen to the cover such as liquid damage or tearing during a move, you can easily reinstall a new outer covering rather than being forced to purchase a new mattress. Tears, damage to mattress surface, and liquid damage to mattresses is not covered by mattress warranties.

Keep in mind one important bit of advice when choosing and buying a mattress, no matter what any mattress salesman tells you—falling in love with your mattress doesn’t happen in one night.

If you bought a bed in a box mattress and you seem to match the performance and the comfort level advertised, and you even came within the moon’s distance from Earth on picking the right mattress, chances are with a little adaption, it’s going to work.

And likewise, if you went the brick and mortar store route, just because you laid down on 10 different models in the store doesn’t necessarily mean you nailed it. Think of it like holding a cup extended out in front of you. It’s not a bother at first but quickly becomes a task even the Hulk couldn’t complete.

Muscles get tired, sore, and start to cramp over time. Unless you talked a mattress store into giving you an overnight sample you’re never going to understand how well a mattress will meet your needs until your sleep on it.

To help mitigate this risk make sure anything you buy—whether it’s from an online seller or local store—offers some type of in-home trial period during which you can return your mattress for a full refund.

');