Natural Latex Mattress Reviews: Updated For 2023

If you’re curious about a natural latex mattress and have been wading through online brands and reviews, you might be wondering what the big deal is, and how to tell them all apart. First off, almost all foam mattresses sold online that are not made using natural, botanically derived latex, are made using petroleum based materials, formaldehyde glues, and fire barrier chemicals.

These include memory foam mattresses, gel foam, urethane, polyurethane, and textiles that are quilted with foam. For the most part, most people do not have medical reactions to these materials, but often they can be subtle. Asthma and even anaphylactic reactions have been reported with individuals who might be more sensitive to VOC’s (volatile organic compounds).

Here is a possible list of toxic materials that can be found in a mattress that contains synthetic foam:

- Volatile Organic Compounds (VOCs): these groups of chemicals very quickly release odorsinto the air. They have been linked to respiratory issues, headaches, and other health problems. Examples of VOCs that may be present in polyurethane foam include formaldehyde, benzene, toluene, and various flame retardant chemicals.

- Flame Retardants: Polyurethane foam is often treated with flame retardant chemicals to meet safety standards for fire resistance. Some of these flame retardants, such as poly-brominated diphenyl ethers (PBDEs) and chlorinated tris (TDCPP), can cause serious health issues, including developmental issues, hormone disruption, and can be carcinogenic.

- Isocyanates: Isocyanates are reactive compounds used in the production of polyurethane foam. They are a critical compound in the foam-forming process, since they create the microscopic bubbles inside. Excess isocyanates or incomplete curing can lead to off-gassing of these compounds. Isocyanates are known respiratory irritants and can cause asthma-like symptoms and other respiratory problems.

- Formaldehyde: Formaldehyde is commonly used in the production of various building materials, including polyurethane foam. It is a VOC and is classified as a carcinogen by many health organizations. Long-term exposure to formaldehyde can lead to respiratory and skin issues, as well as an increased risk of cancer.

- Phthalates: Phthalates are plasticizers used to make polyurethane foam elastic and stretchy. They are associated with endocrine disruption, reproductive issues, and developmental problems. While they are not always directly added to polyurethane foam, they can be present as impurities or as a result of the manufacturing process.

- Antimicrobial Agents: Some mattresses may contain antimicrobial agents to prevent the growth of mold and bacteria. These agents can also contribute to indoor air pollution and may have potential health risks.

for example

Why not just buy a clean, green, natural latex mattress, in the first place?

A latex mattress offers a clean and truly non-toxic bedding option that not only is longer lasting than synthetic foam, but is also far more comfortable. Let’s look at the history of latex mattresses. As the senior editor of this site, being a retailer myself for years in the natural latex mattress business hopefully gives me some serious street credibility when it comes to coaching people on the best brands out there.

If you want to buy a clean and green mattress, that’s one thing. I’ll tell you a little secret, though. A natural latex mattress also happens to be the most comfortable, yielding, and cradling kind of mattress you can buy. You won’t bottom out in one, it cradles and floats your hips and shoulders, and you won’t wake up with a runny nose after sleeping on one.

How natural latex mattresses quickly became the first green bedding option

In 2007, I started one of the first online mattress stores that sold a pre-compressed natural latex mattress direct to consumers.

I got into the latex mattress business, because even back then, there were endless polyurethane foam mattresses beginning to show up in brick and mortar stores, and e-commerce sites were beginning to pop up everywhere, when digital marketers and venture capital companies saw the potential selling compressed and rolled polyurethane mattresses. Seriously, everyone was selling the same slabs of foam.

That’s 15 years ago, and although big money has largely taken over the “bed in a box” concept, and the term “bed in a box” is actually a trademarked name, it turns out that the only kind of materials that you can purchase in a foam mattress that is not petroleum based, is botanically derived natural latex.

The exception to this would be woven steel coils, which if individually pocketed, can be a real asset to a mattress if you need that kind of support.

Customers were looking for natural bedding alternatives, and not everyone wanted to put up with the chemical fumes that spewed from memory foam and other foam materials, causing headaches and watery eyes. I wanted to create a lineup of chemical free beds that were safe, durable, and really comfortable.

You have to be careful when shopping for a latex mattress- a lot of what is offered out there is actually not botanically derived.

My company was called Habitat Furnishings, and my lineup of natural latex mattresses were made top to bottom with pure, botanical product, using no synthetic latex, known in the business as “SBR”, or styrene butadiene rubber, also a petroleum based product.

I sourced clean and triple rinsed Dunlop method latex that contained zero synthetic ingredients. The companies I recommend today to you offer strictly plant based latex material.

Plant based latex will not crumble, desicate, pill, or crack and dry out over time, like memory foam and gel foam will do eventually.,

Where the cleanest, purest kind of latex comes from- and how it is collected and turned into the jiggly, bouncy concoction that makes it the best sleep surface EVER.

To avoid using synthetic latex in my own recipes for my mattress line, I purchased container loads of pure natural rubber from Sri Lanka, India, and occasionally Viet Nam, from plantations that had the highest quality and the creamiest, cleanest latex available.

The liquid latex is hand collected on plantations that contain hundred of thousands of Hevea brasiliensis trees. These trees produce liquid latex for up to 40 years, then can be replaced, harvested as a fine carpentry grade wood, with new saplings growing into the white sap producing trees.

The liquid latex is consolidated and poured into trucks the size of a typical dairy tanker, and hauled to production facilities near the coast where it is vulcanized into cores.

The cores, which are blocks of solidified latex are then cut to American standard mattress sizes.

Vulcanization is a process where liquid rubber is poured into what look like giant Belgian waffle irons, and the liquid is flash steamed, converting the liquid latex rubber into its wonderfully spongy, super elastic, and buoyant solid form.

The blocks of solidified latex are cut and adhered together in American sizes, covered with a natural exterior mattress encasement like wool, organic cotton, or bamboo fabric and can be pre-compressed for shipment. Upscale models include coil systems for added support and comfort.

The Amazing Qualities Of Natural Latex Don’t Just End With Superior Comfort And Support

Plant based natural latex is hypoallergenic, and has no odors, many of our customers who had medical issues, allergies, fragrance sensitivities, or other issues would buy multiple mattresses from us for friends and family. And, since pure latex rubber has a lower pH (more acidic) than most other foam materials used in mattress building, it is also mold and mildew resistant.

Ever opened up a couch cushion and wondered what that brown and crumbled yellow cake-like material is? Natural latex will not turn yellow and dry out like petroleum based foams, especially when exposed to sunlight. Unlike photo reactive foams that turn brown and become brittle, pilling off at the edges like an old sofa cushion, natural latex can retain its supple and highly elastic qualities for up to 50 years.

Natural latex is also anti-microbial, anti-fungal, resistant to mold and mildew as well, repelling dust mites, eliminating mold spores, and providing, essentially, and anti-septic sleep environment. Bacteria are naturally repelled by natural latex due to its acidic qualities.

The only truly chemical free mattress: an interview with a natural latex mattress expert

“The fact is, if you want a truly chemical free mattress that does not off gas fumes either from polyurethane foam used in virtually all mattresses, or from formaldehyde based adhesives used to laminate layers together, your best option is an all natural latex mattress”, says Anderson.

Among the amazing qualities of a natural latex mattress besides the fact that is the only kind of mattress you can buy that is truly chemical free is the comfort level. A pure latex bed distributes weight sideways rather than down, which spreads weight laterally and creates a king buoyant and levitating sensation.

“Imagine spreading pizza dough on a pan, and pushing it to the edges”, explains Marc Anderson, comparing it to typical petroleum based materials like memory foam and polyurethane foam, which create pinpoint pressure spots that also get hot.

Another quality of pure latex is the fact that it will fill many void areas, especially is you are a side or back sleeper. Pockets such as between hips and rib cage or between shoulder blades if you sleep on your back, provide additional buoyant and uplifting support that minimize muscle fatigue and allow your body to relax.

Typically a pure latex mattress is made using a higher density base or support layer, and softer layers towards the top. Many manufacturers also use water based adhesives to laminate the layers together, rather than formaldehyde based glues, which often off gas fumes for very long periods of time.

Different degrees of firmness from model to model can be achieved to appeal to a vast array of body types and preferences, from soft sumptuous, and nest like, to more resilient and supportive densities that offer very little nestling in or sinking. These densities can be controlled simply by increasing or reducing the amount of air that is bubbled into the mixture as it is being poured in its liquid state into the mold.

“I recommend a medium level of firmness for the first time buyer, and typically this will work for about 90% of folks buying their first pure latex mattress”, says Anderson.

Marc would not rule out considering companies that design and build latex hybrid mattresses as well, to help conserve on cost a bit, since a pure latex bed with no polyurethane foam in the support or foundation layer.

A latex hybrid generally will have a fairly thick latex layer on top, usually about 3-4”, but no less than that for ideal results, and the design may include a pocketed coil layer or other kinds of foam layers, all stacked on top of a dense layer of polyurethane that is generally about 6” thick.

“Hybrid latex mattresses are fine as an inexpensive alternative to a top to bottom latex mattress, as you will save a few hundred dollars”, mentions Marc, who also added that the hybrid version will be much lighter in weight and easier to handle.

Most companies selling natural latex mattresses generally use a natural outer covering material, too, like organic cotton, bamboo, or even hemp based fabrics. These fabrics are highly breathable too, and help ventilate a latex mattress, helping it to sleep cool and comfy.

Features And Benefits Of natural Latex Mattresses

Here’s a list of benefits that you will get by sleeping on a pure latex mattress, and our list of recommended dealers that sell both pure latex top to bottom as well as hybrid models is shown right below.

Pure botanical latex contains no VOC or petroleum based materials

Pure latex is anti-microbial, anti-dust mite, and is mold and mildew resistant

A latex mattress distributes load to the side rather than down, eliminating pressure points

Will not off-gas smelly fumes or fragrances making them ideal for people with sensitivities that may trigger headaches

Latex mattresses can last for up to 50 years without degrading

Latex mattresses resist indentations and rutting, unlike polyurethane foam mattresses which dominate the online bedding industry and have family short lifespans

Offers better edge support than polyurethane foam beds

Review: Why A Natural Latex Mattress Is Simply the Most Amazing Mattress You Can Buy

The most popular mattresses on the internet today are foam mattresses that can compressed and rolled, shoved into a box, and delivered directly to your door.

The most popular brands have so many competitors and knockoffs, however, that they are trying to invent new kinds of high tech materials for mattress making, or even other products, to stay relevant and above water financially.

There’s one kind of mattress out there, though, that is quickly rising above the rest. It consistently outperforms all other mattress variations, including memory foam mattresses, coil mattresses, so-called hybrid beds, number style air beds, and more.

Because a latex mattress is made with a naturally derived material and not a petroleum distillate, which is the primary ingredient in every other kind of foam mattress in the industry, it’s healthy, there’s not off-gassing of harmful fumes, and it’s safe for your children.

A natural latex mattress is also naturally anti-microbial, fending off bacteria, viruses, fungal organisms, dust mites, and even mold and mildew. They also don’t break down due to sunlight exposure, won’t pill or turn yellow like virtually all other foam beds will eventually do, and have a lifespan of – wait for it – fifty years or more. Meaning, you can give this mattress to your grandchildren, because it won’t pack down or develop ruts over time. Check this out:

A lot of the popular bed in a box brands start to run together, usually made of a stiff layer of thicker foam on the bottom, then finished and topped off with a ubiquitous layer of blue memory foam, or a piece of softer, squishier foam with a catchy name like “Dream Foam” or “IntelliFoam”, aimed to make the mattress appear fresh and revolutionary in any ever tighter and fiercely savage market.

Hundreds of new brands are now competing in a much more astute space, with a discerning customer base that frets over the details.

There’s one kind of mattress that has steadily risen in popularity above the sea of petroleum based foam beds that are scattered across the landscape of the internet mattress craze, which started gathering steam in 2016.

That bed is a natural latex mattress, which already has a cult following made up of worshippers who understand the astonishing nature of this chemical free mattress, made from the cultivated and hand collected, milky white sap of the Hevea brasiliensis tree- the rubber tree.

In fact, I started out in the bed in a box mattress business designing and selling the web’s very first pure latex mattress, made using only botanically derived latex foam, and even used a water based, non-formaldehyde adhesive to glue the layers together.

My company was called Habitat Furnishings, and in over ten years of selling our clean and naturally derived best, we produced over 275,000 latex mattresses.

Many customers ordered them for friends and family after first experiencing their own mattress, and at one point, we could barely keep up with demand, as we imported our foam “cores”, the vulcanized slabs of 6” thick layers, shipped by container vessel from the island country of Sri Lanka.

Unlike foam beds that are made using petroleum based extruded foams, often with dangerous ingredients needed to “set” the foam or blow it through microscopic nozzles, ingredients such as heavy metals, PBDE’s (known to cause cancers) formaldehydes, and VOC’s (volatile organic compounds), natural latex is a pure, clean, sustainable and renewable resource.

Plant based latex is an all-natural product which comes from the sap of the rubber tree, Hevea Brasiliensis. Latex looks very different before it is processed into products such as mattresses. You may be wondering how the milky-white liquid sap is made into a comfortable relaxing mattress.

The rubber tree, Hevea Brasiliensis, grows in many tropical areas, including Sri Lanka, and other areas in southeast Asia. A mountainous and semi-tropical environment is needed for the plants to thrive. The trees can also thrive in parts of South America.

This tree produces a sap which contains latex, and this sap can be tapped to flow out of the tree and be harvested. Most of the plantations which are responsible for the commercial production of latex are found in Southeast Asia.

Rubber plantations are managed carefully to ensure consistent growth of new trees for output. This is important, because it can take around six years for a rubber tree to grow large enough to have its sap harvested. Note that each tree can live for 100 years.

As an example, Sri Lanka is a massive island, largely dominated by massive rubber tree plantations. Using a regimented, yet almost ancient technique, hundreds of thousands of trees are tapped, and their sap hand collected and consolidated, the liquid milk being poured into massive machines that look like Belgian waffle irons, where the liquid material is quickly solidified (called vulcanization) into a bouncy, jiggly, and creamy solid that defies imagination.

To tap a rubber tree, a collector will make a thin cut on the diagonal to remove a small piece of bark. This allows the sap (i.e. latex) to run out of the bark down the tree and this fluid is collected in a bucket. However, the flow will stop after about 6 hours, but the tree may be tapped again with a new cut the next day.

HOW MUCH LATEX DOES IT TAKE TO MAKE A MATTRESS?

An immense amount of latex is needed to make a mattress. However, remember that latex can be tapped without destroying the tree or creating pollution, unlike other types of mattresses. To make a queen size latex mattress, it will take a whole day’s output of 12 acres of rubber trees.

But instead of harming the environment, these vast expanses of rubber tree groves will, over the course of one year, remove 143 tons of carbon dioxide from the air.

Furthermore, this same 12 acres of rubber trees will keep 8 rubber tappers employed too, creating important jobs in areas where jobs may be scarce.

In other words, when you purchase a latex mattress, you are helping the world environment. You are doing this by supporting the growth of rubber tree plantations and in doing so removing carbon dioxide from the air. You’re also creating much-needed jobs for people who tap rubber trees.

HOW IS THE LIQUID LATEX MADE INTO A MATTRESS?

It seems strange at first to think that the milky sap of the rubber tree can be turned into a mattress! Yet it can be done. This step is called processing. There are several different methods that the latex milk can be processed into a comfortable foam mattress block.

In common to all of them, the liquid latex sap is first mixed with a small proportion of materials which will later help the latex solidify. There is no ‘right’ or ‘wrong’ manufacturing process; they each have different advantages and disadvantages. Essentially, there are two methods of producing solidified latex derived from the original liquid material tapped from the trees.

Dunlop method

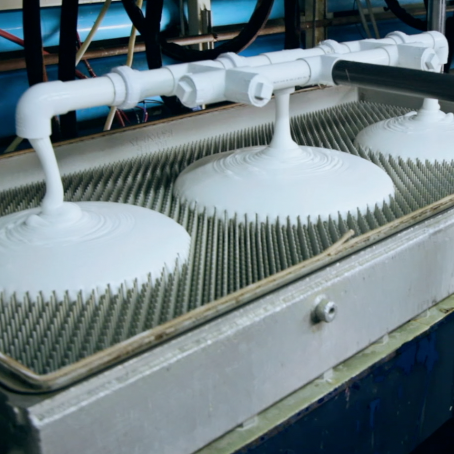

In the Dunlop method, the liquid latex formulation is first mixed so that it will foam. This foamy mix is placed on a conveyer or into a shaped mould, and is then passed into a special oven which quickly solidifies the mixture and allows it to cool.

The latex core is then removed from the mold, and he product is then passed on to the washing station, where residual small amounts of liquid latex and any unreacted solidifying agents are washed away. The latex foam block is then dried by hot air and is ready for use.

With the Dunlop method, the latex foam may be created in any shape that is needed; for example a king size mattress may be prepared in one mould.

Talalay method

The Talalay method is a modified and slightly more technical process than the Dunlop method and produces a slightly different texture of latex, softer, and silkier in feel. With the Talalay method, the liquid latex formulation is transferred into a shaped mould and sealed closed.

Then a vacuum is applied, and the purpose of this is to disperse the latex evenly throughout the mould. After that, it is flash frozen, and then flash heated so that it will permanently solidify. After cooling, the solid latex block is removed from the mould and is ready for use.

The Talalay method cannot be used to produce very large blocks of latex, so latex mattresses made with this method are created from smaller blocks glued together. Locations of the seams may vary, and this is something to take into account when purchasing a Talalay mattress.

There is variation in the technology of making a natural latex mattress. In Europe one company uses special molds and an air bubbling process to create solidified cores that have a broad range of densities and levels of comfort.

Firstly, the latex formulation is mixed continuously with compressed air in order to create foam. Once the latex foam has the right density, minuscule air bubbles are mixed into it. In this way, air is infused into the compound resulting in an open cell structure.

It is these open structures that gives the mattress the required air circulation and guarantee an agreeable temperature in bed. Once the latex foam is ready, a robot spread it into a mould which incorporates pin core holes to define the pattern of the mattress comfort zones. The filled moulds are then vulcanize, in other words baked.

The comfort patterns of the mattress are defined by the pin core structure in the mould, bigger pins make bigger holes in the core and the mattress feels softer. The adapted firmness of the different zones ensures perfect lying comfort.

After the vulcanization step, the fresh latex core is then taken out of the mould and thoroughly washed. The remaining residue is removed completely and the core dried. Each mattress core is tested and examined individually to measure the hardness, the density and is reviewed for visual perfection.

Once the mattress has been rigorously checked for its quality, it then goes to the automated warehouse where it is packed and stored. Soon after that, it is shipped under carefully controlled conditions to customers around the world.

Most natural latex mattresses are graded and then certified by different independent organizations and can carry a full pedigree which consists of several quality certificates. These certificates give customers and users the guarantee that every latex mattress is synonymous with exceptional comfort and safety, and that it is not contaminated with harmful or unnecessary ingredients or agents.

Latex is a natural material which is produced from the sap of the rubber tree. This liquid sap is made into a comfortable solid foam block using one of the processes outlined here. When you buy a 100% natural latex mattress, you are helping the environment by supporting the growth of rubber tree plantations, which remove carbon dioxide from the air.

You are also providing jobs for rubber tappers in areas where employment opportunities are often scarce.

A natural latex mattress goes above and beyond the delicious comfort you’ll feel when you lie down. It’s also about the satisfaction you’ll feel in knowing you’re purchasing an environmentally responsible product.

Although a natural latex mattress can cost a little more than a polyurethane foam bed available from most online mattress stores, the benefits of a natural latex mattress clearly outweigh the performance of these less expensive mattresses.

For example, natural latex is more yielding, yet pushes back against your weight, offering a more buoyant sensation that makes you feel like you are hovering on top of the bed, not being consumed by it. Imagine spreading pizza dough with your fingertips across a pizza pan.

That is essentially how a natural latex mattress distributes your body weight. This lateral load dispersement is unique to latex, and keeps pressure points from causing pain and muscle strain while you sleep.

Natural latex is also easier to turn on, making moving from side to side much easier, allowing you to sleep deeper, rather than constantly waking up as you dig your way out of your mattress to turn or reconfigure yourself.

Because natural latex is highly flexible and immediately responsive, there’s not melting sensation or sensation that you are trapped in your mattress, like memory foam. Latex is ideal for restless sleepers, light sleepers, and for those with back issues, shoulder pain, and neck pain.

Natural latex tends to fill in pockets or void areas, so that your muscles are relaxed and not building up lactic acid, causing soreness and pain while you are sleeping.

');