What Is A Bed In A Box? An Expert Weighs In

how to choose the perfect mattress from hundreds of options: an insider’s guide

Ever wonder why a mattress sold online is referred to as a “bed in a box”? This nickname generally refers to mattresses that have been either compressed or vacuum packaged, rolled, and then inserted into a box that can be easily transported to the end user.

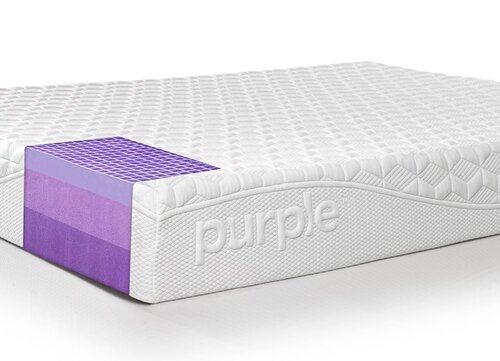

The bed in a box mattress option now dominates the mattress industry as trips to conventional retail mattress stores have steadily declined since the phenomenon took hold as far back as 2014. Business is booming for the global mattress industry with sales growing from $17 billion in 2017 to $43 billion by 2024, according to Statista.Com. Companies like Purple, Saatva, and Casper dominate the bed in a box category.

Hundreds of others quickly followed, until by 2016, consumers became dependent upon reliable review sites to help them make a choice. The dust and cobwebs had been blown off of the tired and wheezing bedding industry, and the mattress business was reinvented overnight. Home Depot, Costco, Wal-Mart, every where you look- except for grocery stores, at least for now, are in the mattress business.

With over 300 hundred foam mattress retailers joining the market in the last five years, thanks to what is termed the bed in a box model, it’s easier than ever to create a bed, find a fabricator, and launch a site with sweeping graphics of twenty somethings chilling in their lofty bedrooms with salvaged wood floors and rescued greyhounds. The image is the same from site to site, a gleeful couple falling into a cloud like mattress that dissolves all of life’s problems away.

Though the bed in a box concept is actually pretty old technology that dates back as far as the late 90’s, it’s reinvented the landscape of the mattress business. In fact, it’s considered one of life’s awesome experiences to order a bed in a box and watch it expand and literally self inflate in your bedroom. Everyone posts their mattress delivery experiences on social media.

The technology used to carefully flatten and roll a 12″ tall mattress down to as little as 3″ tall, and then roll it up like a cinnamon roll is pretty cool, actually. These “roll pack” machines use gentle pressure and even vacuum packaging to remove air and reduce the thickness of a mattress, even folding it over, without damaging it, so that it quickly re-inflates and pops open to its original size.

The roll packing machine I mention are giant assembly line devices that suck in a foam mattress on one end, mash it from twelve inches down to 3 inches, roll it up like a carpet, stuff it into a box, and slap a UPS label on it.

The consumer receives the box, almost like a pizza delivery, and you simply open the box, cut the plastic, and the mattress magically reinflates to its original size within minutes.

Five minutes later, you’re napping with your cat. You’ve just received a foam hybrid mattress. But will it last?

“The real genius behind the mattress disruption revolution is the equipment used to roll and compress the product”, says one expert, referring to the massive hydraulic machines, which can apply tons of pressure, and cost upwards of $400,000 each. Fabrication houses all over the U.S. have purchased these devices, and the number of mattress retailers that use these companies to fulfill and ship their products keeps expanding like a mushroom cloud.

Shopping For A Mattress Online Is Easy, And The Product Is Probably Better Than Retail Store Brands

Younger mattress buying customers today have no conception of sacrificing an entire Saturday traveling to a mattress store, listening to a pinky ring wearing salesman drone on and on about his opinions on foam vs. springs, hovering directly over you as you try to figure out what each bed is supposed to feel like while they are wrapped in plastic, and then wrestling a bed home strapped to the top of your car.

Only about 30% of mattress shoppers actually visit a retail store these days, but why is it that most consumers will easily spend $1,000 without ever sitting or lying on a mattress.

It’s largely because of just a few factors, including online mattress reviews, influencers who love the product, brand recognition, and the fact that most online companies give you the ability to return a mattress- free of charge- so you can simply try out another one.

Also, shopping for a mattress in person is awkward, results in hurried decision making, and doesn’t give you the ability to really test drive the product, either.

The thing that concerns me is that while it’s easy to find a mattress online, most consumers are largely getting caught up in the visual appeal of a web site and the co-called tech sold with the latest mattress options out there.

Not a whole lot of interest is placed in the components used to build a really great mattress that will last. Remember, to keep you grounded, when you buy a mattress, you are essentially buying a giant slab of foam, either with springs in it, or not. That’s where we come in.

Virtually all of the online mattress companies out there are digital marketers first and foremost- not sleep or materials experts. Because it is so easy to create a drop ship, bed in a box model business, I’m concerned that the competition is so intense that many foam mattress retailers have been forced to import “absolute garbage” to fill out their product (filler layers are commonly used to increase mattress height and perceived value of the mattress in question).

Sometimes these layers are made using discarded and shredded garment fiber mixed with recycled plastic, made to create mats whose sole purpose is to increase the height and overall appearance of a mattress.

I’ve built mattresses myself and have had to use materials that simply add height or visual appeal to the design, but the quality of the filler foam used today is vastly inferior to what I used even six or eight years ago. Yeah, you can buy a mattress for $400, or even less, but it’ll be a door mat in two years”.

Let’s get to it, though. We know the brands. Their ads following us around everywhere we go, saturating our minds with an endless carousel of hyper-advanced marketing techniques on social media and YouTube, and lining the innards of every so-called third party “review site” that jockeys for position on the first page of your search results.. These companies have turned the sleepy brick and mortar mattress marketplace upside down. And they’ve done it with style and creativity like we’ve never seen. Ever.

WHAT MATERIALS ARE USED IN A typical bed in a box MATTRESS AND WHAT FUNCTION DO THEY SERVE?

A typical foam mattress is very simply a mattress made using two or more different kinds of unique materials so that you can capitalize on the benefits of all of the components used, even better than say, if you had purchased two separate beds with just one of the key ingredients.

In almost all cases, either the base or foundation layers and in many cases the top comfort layers, are made using polyurethane foam, memory foam, or latex foam.

Generally, these three basic kinds of foam are latex rubber, memory foam, and a synthetic foam material referred to in the industry as polyurethane foam, also known as HD or HR foam (high density and high resiliency, respectively, but we’ll just call them synthetic foam for simplicity’s sake).

The poly foam, as its called in the business, is usually the bottom layer, forming the foundation or base of the mattress. This layer is typically pretty thick, and it’s very inexpensive. It’s the most profitable part of a foam mattress, and generally where quality is sacrificed…big time.

Right above the thicker and firmer bottom layer, you’ll find another area where lots of money is made, that is, if you bother to look at the cutaways and graphics describing what you are getting for your money. It’s referred to as the comfort layer section and provides the characteristic underlying softness or firmness of a particular model of mattress, as you work your way to the top or “finish layer”.

The comfort layers and top most components give each brand it’s signature “recipe” and is generally where retailers will incorporate a whole lot of fluff and language about proprietary materials, unique designs, and patented this and that.

If a company is using esoteric names like “Dreamfoam”, “Ultrafoam”, or “Plushfoam”, you can be sure that it’s merely marketing fluff, and don’t be afraid to ask whether or not the material is polyurethane foam, urethane (memory) foam, or latex rubber, or a combination.

It’s likely that these proprietary ingredients are acceptable, since these companies generally work tirelessly to improve the materials they are using to reduce return rates, typically the most costly component of any mattress business offering generous return policies (the industry standard for beds that are returned during a trial period, merely because a person doesn’t find them comfortable, is 15%).

When contemplating a foam mattress, get educated before you go shopping around. Ask questions like, “who makes your bed and where?”, and “where do you source your foam?”. Ask if the beds they sell are appropriate for your sleep habits, whether it be back, belly, side, or flip flopper.

To begin with, most foam beds are built for and designed to accommodate folks within a weight range of 100-210 lbs. If you’re over that weight, you should consider a specialized foam mattress using densities that are higher. There are now several online stores that make mattresses strictly for larger people.

Highly niche, but addressing a real need for bigger sleepers- a growing segment of our population. Couples who weigh in at more than 200 lbs. each and buy the typical bed in a box or even coil type bed from a local retailer, often find themselves swallowed hole in the bowl formed by the bodies in the center of their mattress, only to return it within weeks.

It’s also important to understand how a mattress is made, and what the best specs are for a typical well made hybrid bed. For example, for the upper layers, or finish layers, we recommend with at least 2.2 lbs density foam (the weight of a cubic foot of the material) to deliver proper support and cushiness.

This density is pretty standard, and is essential to provide uplifting and decent support without bottoming into the material beneath. The bottom layers, or support layers, should be more dense, let’s say in the 4-5 lb range.

memory foam: the greatest invention of the 20th century?

Another unit of measurement for foam mattresses is something called ILD, or Indentation Load Deflection, which is the amount of weight it takes to depress one cubic foot of foam 25% of its original height of 12″, when a solid plate is applied to a one square foot area.

You should look for ILD’s of 30-35 for bottom, supportive layers.Another popular kind of hybrid bedding component, typically referred to as Memory Foam, also called “visco-elastic foam”, is an amazing material that I believe is the true staple ingredient of any foam or bed in a box type mattress.

Technically, it is urethane foam, manufactured using a special technique that creates a vast network of permeable bubbles, that move air in and out very slowly, thus giving it a very unique feel. If you like that wonderful “melting in” feel that it is known for, and have pressure issues, definitely consider it within the recipe of the mattress.

Made originally by NASA for use in fighter aircraft seats for shock absorption, it should be close to the top in the mattress you are considering, so you get the best benefit, and memory foam should be at least 4lb. density or higher, as it will last longer, will not be likely to form indentations, and will be supportive and quite yielding. Memory foam that is 3lb. density, commonly used in these kinds of mattresses, simply won’t hold up. I’ve seen poorer grades of memory foam split and crack simply due to body movement on a bed.

Memory foam is used in about half of the most popular mattresses sold today. Great stuff, just make sure it at least 2 inches thick, and is flat, not corrugated or “wavy”, as this weakens the supportive qualities of the material. It also works well with our next ingredient, latex rubber. Chat with or call your potential retailer and make sure you’re getting the best memory foam available.

Memory foam is often given mysterious names, without any technical description, including density, which is critical. If a mysterious layer of foam used in a mattress you’re considering is called “Sparklyfoam”, don’t be nervous, but ask questions and find out what it is. The minute you do that, you’ll be respected further and whether in a store or chatting online, you’re in charge at that point.

Latex rubber foam has been around longer than almost any other foam material used in bedding. Sears sold pure latex rubber mattresses back in the late 50’s, and millions of Americans hauled them home over the next 30-40 years. Latex went through a bit of a dormant phase when synthetic foam came along, but then enjoyed a renaissance as more consumers sought out cleaner, greener, all natural ingredients for their beds.

Used in many popular foam mattresses sold today, latex is purely wonderful stuff, bordering on frigging amazing. Hand collected, and then converted from liquid to a solid sumptuous and jiggly form, it’s great for a lively, buoyant, and uplifting feel. If you are considering a latex mattress or a mattress with latex in it, make sure you are getting pure latex, and not synthetic latex, as the natural material is livelier, lasts longer, and it won’t yellow and dry out over time.

If it’s in a mattress you’re looking at, make sure you get 2” at least, at or near the top (especially if its mixed with synthetic foam) and if you’re looking at a hybrid bed (any bed that has one or two different kinds of material adjacent to one another, meaning practically every mattress out there these days) make sure it’s right above or below memory foam if you want both ingredients.

Probably the most interesting qualities about all natural latex material is that is naturally anti-microbial, resists dust mites, won’t collapse or indent over time due to its cellular structure, and is great for tossers and turners because it pushes up and to the side, allowing for easy turning without waking you up. It’s kind of like spreading pizza dough on a pan, it distributes its load sideways instead of down, and you tend to “float” above it.

Ask and make sure you’re getting either pure latex, either Dunlop latex, or natural Talalay, and not a blend. Often there is no distinction made between the pure, more expensive foam, and the cheaper synthetic version. Call or chat with your potential retailer. Much longer lifespan, and better bounce!

Also, if you’re looking for an all natural bed, you’re probably going to want to steer clear of synthetic polyurethane foam, and go with a top to bottom latex mattress. However, most of the biggest sellers out there are made using polyurethane foam. This material is generally the most important component in any foam mattress.

WHAT IS POLYURETHANE FOAM?

Polyurethane is a polymer material made from reacting different monomer materials; isocyanates and polyols both derived from refined crude oil. Polyurethane foam is the most common upholstery material used today. It is found in almost all mattresses, sofas, the seats in your car, spray foam insulation and more.

About a third of the composition of memory foam or polyurethane foam is created from Polyols. Essentially, it is a form of alcohol, which is almost always made entirely from petrochemicals. There are some polyols containing plant based alcohols (soy, castor bean, tea tree, aloe, et cetera), in very small percentages.

You might see ads for “soy based foam” or “organic polyurethane foam” which can be very misleading. These foams are often labelled as natural, but the majority of the finished product is not natural and there is zero health related benefit to using plant polyols in polyurethane foam production.

To convert the liquid material into a foam, which contains lots of minute bubbles to give it elasticity and spring back, an ingredient called a blowing agent is added to the mixture. This is a chemical in the form of a gas which is blown into the mixture to turn it into foam, essentially aerating the mix. Different types of polyurethane and memory foams simply use different blowing agents.

Some foams are water expanded, which is another clever way of suggesting that somehow the foam is natural. This is simply green washing. The process of making polyurethane is typically not as sophisticated as most would think. Although there are other methods for making ‘continuous’ pieces of foam on more expensive machinery the crude single batch method in the video below can produce foam of the same quality.

A typical foam mattress sold today might be a combination of polyurethane, latex and specialized polyurethane foam known as memory foam. Each has very unique benefits. Natural Latex is collected from trees, is chemical free, highly elastic, buoyant, and spongy and cushy, while memory foam fills up around your body offering pressure point relief, cradling you as it fills in void areas and pockets as you melt into it.

The polyurethane foam is typically used for the foundation or base piece, but can also be used for top comfort layers when it is fabricated as softer and spongier.

Other foam mattresses combine memory foam with gel foam, or even thin layers of springs, called microcoils, or other exotic materials like New Zealand free range wool. Some offer their own variety of proprietary foam, giving them unique names, like “Dreamfoam” or “Ultrafoam”, transforming ordinary synthetic foam layers into mystical and magical sanctuaries for us to nestle into where we dream of faraway lands and princesses and we don’t ever want to get out of our beds.

There are hundreds of options that make it so confusing to buy a mattress, you feel as if you are buying a used car. We’ll help you narrow down the options, though, to get you a mattress that is comfortable, supportive, and not over priced.

you can buy a really great mattress for under $1,000

The beauty of a contemporary foam mattress design is that the concept follows a minimalist approach, utilizing a few specific ingredients that deliver maximum comfort at a reasonable price. Generally, you can find a mattress like this for under $1,000, though if you want more bells and whistles, such as a more upgraded outer covering, or more than two unique materials inside the mattress, expect to pay $1,500-2,000 or more, especially if it is a brand name. But, as a rule, in today’s shopping environment online, keep your price point at or under $1,000, and you’ll likely be able to score a really great mattress.

Let’s say that you wanted something all natural, for example. You can buy a 100% latex mattress which contains zero synthetic foams, if you are concerned about keeping the mattress purely green, with no synthetic or man-made materials. You’re going to pay significantly more, though than is you go with a hybridized version of some latex, and some synthetic foams. Expect to pay $1,500 or up for a decent pure latex bed.

The trade off is the much less expensive synthetic foam layers, which up until recently, had not evolved much. In the last five years, the technology available with synthetic foam has exploded, and an amazing lineup of material is available.

One of them is graphite infused polyurethane foam, which disperses body heat, another is gel/memory foam combination which offer a sumptuous, cloud like feel, and even firmer, yet comfortable foams if you need a resilient feel with no sinking or collapsing.

It’s also great at dispersing body heat and delivering a unique pressure relieving feel. I’ve also studied a unique foam that suspends aluminum in the mix, allowing heat to be reflected away from the body, in almost a suction like fashion, great for hot sleepers.

Understanding the engineering and design of today’s hybrid mattresses is fairly easy. It’s largely driven by a “layer cake” approach which enables a manufacturer to offer their own unique “cake recipe”, creating what many of these retailers will claim is a “universally comfortable bed” that appeals to anyone.

The trick for these foam bed manufacturers is to create a recipe that satisfies 90% of the customers who get them into their bedrooms. The bed in a box category in bedding is driven by constant testing, and before a bed is put up on a web site, it’s likely been test driven by dozens if not hundreds of users. If the return rate is less than 10%, the mattress will likely be kept in the company’s lineup. You’re not the guinea pig, trust me.

That work has already been done for you. The big players also have a vast number of reviews on their mattresses, and we’ll get to that later, but in the back of your mind, remember that while most every site offers reviews, many of them may not be truly third party, independent reviews. In fact, they may have been paid for.

To build a durable and comfortable foam mattress, construction involves using one ingredient you are looking to exploit the most for comfort as the top layer, and using quality materials as the base or supportive layer to provide the best overall feel. It is important, however, to not overlook the kinds of foam materials that makeup the support layers, as they can fail and develop rutting or depressions over time.

In the case of a foam mattress using a premium top layer such as memory foam, gel foam, or pure latex, what you are likely to find is a 2” or maybe 3” layer of these materials, and underneath you’d likely find a combination of one or two different high density synthetic layers which provide good support and accentuate the comfort of the top layer.

The overall effect is to deliver the same or an even higher level of comfort than if the mattress were made from the same material top to bottom. The best part is, the mattress is likely to be substantially less expensive, and in many cases, much lighter in weight.

IT’S WHAT’S UNDERNEATH it all THAT REALLY ADDS TO LIFESPAN AND DURABILITY

One key consideration though, is the quality of the synthetic high density foams used underneath, which can broadly range in quality from outright utility grade foams which aren’t even designed to be used as bedding grade material, (like foam you would use to pack household goods in a move) to extremely high quality foam layers that are especially designed to be used for support layers in mattresses. Almost all of them are made using petroleum based products, which may be a concern for some folks.

There are new materials and foams out there though that are manufactured without a lot of the toxic ingredients used in the past. Still, though, many people are concerned about synthetic materials being used in their beds, since they are a petroleum based material.

Another really important consideration is how the layers of your candidate mattresses are adhered, or glued, to one another. Believe it or not, this greatly affects the elasticity and comfort of a mattress. Continuous gluing, which means that the entire surface is sprayed with a sheet of adhesive, renders the materials stiffer and less responsive, and can make a mattress feel like styrofoam, rather than squishy, spongy and delightfully sumptuous.

The way around that is to apply the glue only at the perimeter edge of the foam layers, thus preserving the dynamics of the individual foam layers. Basically, a “bead” of adhesive is applied at the edges of each layer. If I were buying a foam mattress today, the first question I would ask in a chat or on the phone is “how are your layers glued together?”

One more important point. The kind of adhesive used can be of paramount importance. Many companies that are producing high volumes of beds per day typically use a quick set adhesive. These glues are fast drying, and are made using VOC compounds that often contain formaldehyde, which can often off-gas or leach out of the mattress for years.

The safest adhesives are water based, but they take skill and longer drying time, and likely a bed made with these more expensive but safer adhesives cost a bit more. When I order a mattress, I get even more particular, by asking for a specific brand of water based adhesive, called Simalfa. It is a completely safe glue material, even labeled for infant and crib bedding use. You can visit the Simalfa web site and learn more, if you’re sensitive to smells, or VOC compounds in general.

ARE FOAM MATTRESSES SAFE, SINCE THEY ARE MADE WITH SYNTHETIC, PETROLEUM BASED INGREDIENTS?

Absolutely. Most polyurethane foams these days are generally considered inert and don’t off gas fumes that last for any length of time. You may notice a slight smell at first, which is normal, and this odor will quickly fade, especially if you let the bed “air out” for a few hours or a day, before installing sheets and bedding.

Although different brands can vary as far as ingredients that create odor, beware if a company is trying to sell you “no VOC or VOC free” memory foam, since it actually doesn’t exist. A memory foam can be “low VOC” or “free of toxic VOCs”, but as we’ve mentioned before, almost every organic product has at least some minimal off gassing that is essentially harmless, but may frighten you at first.

Amazingly, however, there are synthetic foam materials that are made using a proprietary sequence of steps to remove many harmful materials from the process. One example of this material is a specialized foam that is known as Certi-Pur® foam. This kind of foam is free of harmful ingredients typically found in petroleum based foams, like PBDE’s (poly-brominated di-ethyl ethers) which are toxic and achieved notoriety for contributing to ozone layer depletion, as well as formaldehyde, volatile organic compounds, heavy metals, and other toxins, all of which continue to off-gas over long periods of time.

It is available in many densities and degrees of firmness, so that it can be properly calibrated with the top layers of the mattress to deliver the highest level of comfort and support. Here’s a link to the consumer page for Certi-Pur®, which you can check out after reading my article.

Buying a foam mattress can be challenging, considering that most of the components are synthetic, but don’t let that confuse you. Technology has advanced far in just a few years, and polyurethane and other advanced polymer foams have vastly improved in comfort, and can be made in a variety of densities, support, and responsiveness. Price points will vary, but in today’s competitive marketplace, it’s easy to find a decent mattress that can deliver comfort and support, for under $1,000.

Bottom line, it’s easy to find a great hybrid mattress that will fall into the $700-900 category for a queen or a king, and if you order a bed in the box type unit that arrives at your door, typically, if sold with a decent 90-180 trial period, you can test the mattress for a good 30 days to see if it works for you.

Most people determine whether a mattress works for them within three nights, though if you are going from let’s say an innerspring to a foam mattress, the adjustment period may take a few weeks or so. With so many choices out there and a good no questions asked trial with the ability to get your money back, you’re pretty bulletproof from being scammed or taken.

ARE FOAM MATTRESSES SAFE, SINCE THEY ARE MADE WITH SYNTHETIC FOAMS?

Absolutely. Most polyurethane foams these days are generally considered inert and don’t off gas fumes that last for any length of time. You may notice a slight smell at first, which is normal, and this odor will quickly fade, especially if you let the bed “air out” for a few hours or a day, before installing sheets and bedding.

Although different brands can vary as far as ingredients that create odor, beware if a company is trying to sell you “no VOC or VOC free” memory foam, since it actually doesn’t exist. A memory foam can be “low VOC” or “free of toxic VOCs”, but as we’ve mentioned before, almost every organic product has at least some minimal off gassing that is essentially harmless, but may frighten you at first.

Amazingly, however, there are synthetic foam materials that are made using a proprietary sequence of steps to remove many harmful materials from the process. One example of this material is a specialized foam that is known as Certi-Pur® foam. This kind of foam is free of harmful ingredients typically found in petroleum based foams, like PBDE’s (poly-brominated di-ethyl ethers) which are toxic and achieved notoriety for contributing to ozone layer depletion, as well as formaldehyde, volatile organic compounds, heavy metals, and other toxins, all of which continue to off-gas over long periods of time.

It is available in many densities and degrees of firmness, so that it can be properly calibrated with the top layers of the mattress to deliver the highest level of comfort and support. Here’s a link to the consumer page for Certi-Pur®, which you can check out after reading my article.

Buying a foam mattress can be challenging, considering that most of the components are synthetic, but don’t let that confuse you. Technology has advanced far in just a few years, and polyurethane and other advanced polymer foams have vastly improved in comfort, and can be made in a variety of densities, support, and responsiveness. Pricepoints will vary, but in today’s competitive marketplace, it’s easy to find a decent mattress that can deliver comfort and support, for under $1,000.

Bottom line, it’s easy to find a great foam mattress that will fall into the $700-900 category for a queen or a king, and if you order a bed in the box type unit that arrives at your door, typically, if sold with a decent 90-180 trial period, you can test the mattress for a good 30 days to see if it works for you.

Most people determine whether a mattress works for them within three nights, though if you are going from let’s say an innerspring to a foam hybrid mattress, the adjustment period may take a few weeks or so. With so many choices out there and a good no questions asked trial with the ability to get your money back, you’re pretty bulletproof from being scammed or taken.

I’ve scoured dozens of popular web sites for years to try and find a company that offers a really great foam mattress at a reasonable price, with an attractive warranty, and a great return policy if you don’t like it. We looked for BBB A+ ratings, how long the company has been in business, and other factors.

UNDERSTANDING the basic elements of a mattress- BEFORE YOU BEGIN READING REVIEWS AND SHOP FOR A MATTRESS

Polyurethane foam is the essential building block for all bed in a box mattresses out there, and the primary ingredient found in most mattresses sold in retail stores as well. Without it, there would be no substrate upon which to layer up ingredients in the layer cake style of sleep we all indulge in. Gravity dictates that we sleep on slab surfaces of soft and firm ingredients.

ALL polyurethane foam is petroleum based, though there are some foam materials that are made with small amounts of soy based polyols, and can be categorized as somewhat natural, but that’s a stretch. Chemicals are combined, and much like adding dishwashing detergent to a sink full of water and watching suds arise and expand, the polls combine with foaming agents and expand, forming a flexible grid of compressible material. Blowing agents are often used to facilitate this process.

High-density microcellular foams can be formed without the addition of blowing agents by mechanically frothing or nucleating the polyol component prior to use. These foams are not used in bedding, but rather for extremely dense components like shoe soles or tires.

an infinite variety of techniques are used to create very different kinds of ingredients in today’s mattress options

Surfactants are used in polyurethane foams to emulsify the liquid components, like soap does to grease, and stabilizes the cell structure to prevent collapse and allow for spring back. Rigid foam surfactants are designed to produce very fine cells and a very high closed cell content, and this creates very firm foam. Flexible foam surfactants are designed to stabilize the foam and to keep it from shrinking.

Adjusting and controlling these variables permits many different kinds of foam to be made, in a variety of densities, and degrees of firmness or softness. These foams can be tinted too, and can appear in a virtual rainbow of colors, making it easy for manufacturers to create models and styles that have their own unique marketing and merchandising qualities.

Polyurethane foams can be either “closed-cell”, where most of the original bubbles or cells remain intact, or “open-cell”, where the bubbles have broken but the edges of the bubbles are stiff enough to retain their shape. Open-cell foams feel soft and allow air to flow through, so they are comfortable when used in seat cushions or mattresses. Closed-cell rigid foams are used as thermal insulation, for example in refrigerators.

For mattresses, polyurethane foam is delivered to fabrication houses in large blocks called “buns”, and sliced down into the desired thickness and sizes needed to build out a lineup of foam beds. They can be ordered with any desired tint, the foam can be sculpted into unique shapes, all at very minimal cost to the manufacturer. Very often, a thick piece of firmer foam about 6-8” tall is used as the foundation or base layer in a foam bed.

The ideal density for this kind of foam, especially if it is to last for 10-20 years is 28-32 ILD. ILD is a unit of measurement in the bedding and foam industry which describes relative density or firmness. The acronym stands for Indentation Load Deflection, and is characterized as the amount of weight it take to compress one square foot of area one inch in depth.

Thus, a 32 ILD rating would indicate that the foam sample tested required 32 lbs applied to one square foot of the sample to be compressed one inch. This measurement system is also an indicator of quality in foam materials used in these popular hybrid foam beds. A typical well made foam mattress might have this configuration:

MEMORY FOAM and gel foam

Commonly found in most polyurethane mattresses, “memory foam” consists mainly of polyurethane as well as additional chemicals increasing its viscosity and density. It is often referred to as “viscoelastic” polyurethane foam, or low-resilience polyurethane foam (LRPu). Higher-density memory foam “melts” and becomes soft and body conforming when exposed to body heat, allowing it to mold around your body relatively fast. Newer foams may recover more quickly to their original shape.

“Memory foam” was developed in 1966 under a contract by NASA’s Ames Research Center to improve the safety of aircraft cushions in flights where high G forces were involved. Scientists Chiharu Kubokawa and Charles Yost of the Stencel Aero Engineering Corporation were the principle chemists who developed the materials. The temperature-sensitive memory foam was initially called “slow spring back foam”; Yost called it “temper foam”.

Created by feeding gas into a polymer matrix, the foam has an open-cell solid structure that matches pressure against it, yet slowly springs back to its original shape. It was the most significant advance in the foam and subsequently the bedding industry in a century.

When NASA released memory foam to the public, Fagerdala World Foams was one of the few companies willing to work with the strange, alien like material, as the manufacturing process was tedious and difficult. Their 1991 product, the “Tempur-Pedic Swedish Mattress” eventually led to the mattress and cushion company, Tempur-World.

Memory foam was also used in medical settings. For example, it was commonly used in cases where the patient was required to lie immobile in their bed on a firm mattress for an unhealthy period of time. The pressure on some of their body regions impaired the blood flow to the region, causing pressure sores or gangrene. Memory foam mattresses significantly decreased such events.

To this day it remains the one ingredient every foam mattress should include in its design, owing to its amazing pressure point relieving qualities, and its ability to cradle and support the body like no other foam.

Memory foam was initially too expensive for widespread use, but became cheaper. Its most common domestic uses are mattresses, pillows, shoes and blankets. It has medical uses, such as wheelchair seat cushions, hospital bed pillows and padding for people suffering long-term pain or postural problems.

Unfortunately, the heat-retaining properties can also be a disadvantage when used in mattresses and pillows so scientists developed what was known as “second generation memory foam”, and manufacturers began to use open cell structure to improve breathability. In 2006, the third generation of memory foam was developed. “Gel visco” or “gel memory foam” incorporates gel particles fused with visco foam to reduce trapped body heat, speed up spring back time and help the mattress feel softer.

Gel-infused memory foam was next developed with what were described as “beads” containing the gel which, referred to as “phase-change material”, would achieve the desired temperature stabilization or cooling effect by changing from a solid to a liquid “state” within the bead of gel. Changing physical states can significantly alter the heat absorption properties of foam material, which is why the technology was applied to visco-elastic memory foam.

Since the advent of gel memory foam, other substances have been added to create a variety of options that provide comfort, support, pressure point reduction, and other benefits. Aloe vera, green tea extract and activated charcoal have been combined with the foam to reduce odors and even provide aromatherapy while sleeping. Tercel and other rayon based textiles has been used in woven mattress covers over memory foam beds to wick moisture away from the body to increase comfort. Phase-change materials (PCMs) have also been used in the fabrics that are used on memory foam pillows, beds, and mattress pads.

A memory foam or gel memory foam mattress is usually denser than conventional polyurethane, making it both more supportive but also much heavier. Memory foam mattresses are often sold for higher prices than traditional mattresses, because of the process involved and the sophisticated chemistry.

Memory foam is extremely beneficial in many ways. Its open-cell structure reacts to body heat and weight by conforming to the body, and relieving pressure points, and preventing bed sores. Most memory foam has the same basic chemical composition, however the density and layer thickness of the foam can vary the feel of the foam greatly.

A high-density mattress will have better compression ratings over the life of the bedding. A lower-density one will have slightly shorter life due to the compression that takes place after repeated use. Look for higher density memory foam whenever you can.

Ask for 5lb memory foam in the support or middle layers, and 4 lb. density memory foam on the top or comfort layer. Less expensive 3 lb memory foam will ultimately most last as long, tends to split and crack due to body movements over time, and will desiccate (dry out) much more quickly.

NATURAL LATEX FOAM

Latex foam is a manufactured foam product popular in a wide range of cushions and mattress products. All-natural botanical latex is a natural, renewable product secreted in fluid form by a multitude of plant species; most latex used in foam manufacture is harvested from the prolifically productive rubber tree plant, Hevea brasiliensis. There are engineered, synthetic versions of latex foam, but none have managed to match the natural characteristic of real botanical latex.

The rubber tree was originally discovered in the forests of Brazil. Once the value of latex was discovered for a range of manufactured products, the farming of rubber trees took off. A rubber tree blight combined with mobile business speculators in the 1800s and early 1900s led to a glut of large-scale rubber tree estates throughout Asia.

DUNLOP LATEX AND TALALAY LATEX

Dunlop: In the Dunlop production process, first invented in the early 20th century, latex is poured into molds, vulcanized (usually with sulphur), and allowed to dry. In the early days, particulate settling would lead to a Dunlop latex foam that was firmer and denser on one side than the other. These days, with improvement in manufacturing techniques, that unevenness is minimal or even nonexistent.

Talalay: In the Talalay production process, perfected after World War II, the latex is first whipped for aeration, then poured into molds where it’s flash-frozen and subjected to vacuum suction. The result is a soft, space-age material that usually contains more air than Dunlop latex and is usually more expensive, even though there’s less latex and more air in the final product than in Dunlop mattresses.

Both Dunlop latex foam and Talalay latex foam are available in a range of densities and firmnesses, from soft to firm. Dunlop can be firmer than Talalay, and Talalay can be softer than Dunlop.

In the mattress world, most superior mattresses are made using layered Dunlop and Talalay, with Dunlop on the bottom for support and Talalay on top as a “comfort layer”. Latex FAQ: Is Talalay latex better than Dunlop (or vice versa)? The question really should be centered more around how to use Talalay and how to use Dunlop.

SYNTHETIC LATEX VS. REAL BOTANICAL LATEX

Natural latex is a coveted foam bedding that offers body-contouring support and pressure-relieving comfort, all in the same space-age yet sustainable, environmentally friendly material. But not all latex foam beds are created equal. Here are the types of latex mattresses that you might find on the market:

Synthetic: Synthetic latex foam mattresses tend to be less resilient and less comfortable than real foam and may break down more quickly. Pure synthetic Dunlop is such a poor-quality bedding that you’ll rarely find it on the market, but you will occasionally find all-synthetic Talalay.

Blended: Blended latex is usually 70% synthetic latex and 30% natural latex, and can be processed using either the Dunlop or Talalay methods. Blended latex still doesn’t have the plush, buoyant feel of 100% natural latex beds, but it’s a closer approximation than purely synthetic options.

Hybrid Latex: Hybrid mattresses are a latex “comfort layer” over some other interior support, either a polyurethane core, a traditional inner spring mattress, or even an air mattress. A latex memory foam mattress is a particularly comfortable hybrid form, made up of a memory foam interior sandwiched between a latex sleep layer and a polyurethane core.

NATURAL LATEX: simply the best foam component in any mattress

Many people know well that 100% natural botanical latex mattresses are the holy grail of the premium mattress world. But as such, they’re very expensive. And not all all-natural beds are ideal an all-Talalay bed may sound extremely comfortable, but be more likely to sag over time, since the Talalay process incorporates so much air. Synthetic beds can be less comfortable, less resilient, and have shorter lifespans. While synthetic latex may be more affordable, it may not be worth your money on its own. Order samples or lie on a floor model before you buy to be sure you’re happy with the quality.

Blended latex is a compromise on all fronts. It’s an all-latex mattress at a lower price and a reasonable approximation of all-natural latex qualities. But it sleeps like a shadow of an all-natural latex bed almost comparable, but never quite.

Many people swear by hybrid beds, and they can be quite comfortable and often more affordable than other options. Still, inner springs can sag over time, and a firmer polyurethane core can cause your latex comfort layer to bottom out? over time, so that you’re basically sleeping on the harder polyurethane layer.

And watch out! A bed labeled “100% latex” can be 100% synthetic latex. Look for a 100% natural (or at least a blended latex) bed instead. Take your time, read the fine print, and know your product. As a savvy consumer, you’re sure to find an affordable latex mattress that will serve you well for years to come.

my carefully curated list of excellent bed in a box mattress options

BEAR PRO HYBRID MATTRESS

A memory foam mattress that offers a medium firm level of support. 10” finished height, 100 night trial, 10 year warranty, $840 for a queen. Free shipping. Marc’s comments: High tech infrared reflecting outer fabric, carbon infused foam, sleeps cool and cozy. Excellent edge support and resilient base layer. Optimized to sleep cooler, stay fresher for years with activated charcoal foam. Well crafted in USA.

NECTAR PREMIER MATTRESS

A memory foam mattress that employs several innovative gel and memory foam technologies. The result is sumptuous, supportive, yet yielding sleep without deep sinking. 11” finished height, 365 night period, lifetime warranty, $795 for a queen. Free shipping. Marc’s comments: A warranty that lasts forever? Right, it’s true, and they get away with it by using components that last. One of the most popular mattresses in the industry. LOTS of freebies with my link.

PURPLE MATTRESS

One of a kind polymer gel mattress with its own unique feel. Supportive yet spongy and yielding right where you need it. Medium level of support. 10” finished height, 100 night trial period, 10 year warranty, $999 for a queen. Free shipping. The ONLY bed out there using innovative collapsible, or “column buckling” foam technology. Marc is an expert in Purple’s technology, highly recommends. Huge satisfied customer base, consistent 5 star reviews.

KEETSA tea leaf supreme

A memory foam mattress that offers a firmer level of support. 10” finished height, no trial period, 12 year warranty, $940 for a queen. Free shipping. We like them because of their use of bio-oils in their proprietary foam mix which is greener and less toxic to sleepers than conventional foam. Marc’s comments: Spoiler alert: A very firm bed. Perfect for back sleepers and spine health.

NOLAH MATTRESS

A memory foam hybrid mattress with a specialized top layer that eliminates heat and ventilates effectively. Great for hot sleepers who need pressure reduction. Medium plush feel, 10” finished height, 101 night period, lifetime warranty, $1199 for a queen. Free shipping. Marc’s comments: Reviewers say it works for belly, back, and side sleepers. Excels at pressure point relief using top notch memory foam and specialized cooling layer at top.

SPINDLE ADJUSTABLE PURE LATEX MATTRESS

Shipped with three individual layers, allowing you to assemble the mattress in soft, medium, or firm. Organic outer cover, no glue, wool pad pillowtop. Solid 10 year warranty, 365 day no questions asked trial period. Pure dunlop, no synthetic SBR rubber. This is a unique mattress that you customize at home to create the perfect feel and level of support.

THE AWARA ORGANIC LATEX HYBRID MATTRESS

This outstanding natural latex hybrid bed is stuffed with clean, chemical free ingredients and owners love them. You nest upon a breathable organic quilted top, and beneath you, your body floats on 4” of botanical Dunlop latex. Individually pocketed coils suspend and hover you above the base layer of medium high density foam that won’t break down. Delivered with 365 day no questions asked trial and FOREVER warranty! Now, how cool is that?

LOOM AND LEAF BY SAATVA

A memory foam mattress that offers a medium level of comfortable nestle factor, and good back support. 10” finished height, 120 night period, 15 year warranty, $1099 for a queen. Free shipping. Marc’s comments: Pain reduction is the focus of this bed. Another Saatva winner, using cooling memory/gel foam layers, owners love it. Excellent for fitness buffs and athletes.

NOVOS BED

A gel and memory foam hybrid mattress that offers a medium to medium firm level of support. 11” finished height, 120 night trial period, 15 year warranty, $999 for a queen. Free shipping. Marc’s comments: One of few memory foam bed with a whopping 4” of real memory foam. If you love that melt in sensation, and need to be cuddled, reviewers claims it “makes love to you”. Go for it. No other mattress offers the pressure relieving qualities due to thickness of memory foam layer- and the quality. One FAT mattress.

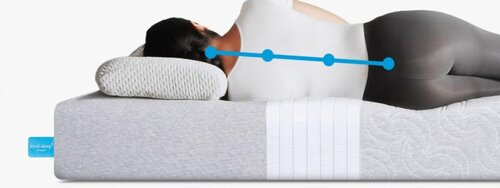

LEVEL SLEEP MATTRESS- THREE ZONES REDUCE PAIN

The Level Sleep Mattress was designed to cradle and support the human form. Three different areas of firmness reduce causes of back pain by applying low pressure and maintaining spine alignment simultaneously. Soft at shoulders, firmer back support, and medium torso. Certi-Pur foam layers, made in USA. 365 night trial. King just $1399 with deal. Hip pain? Save $140 with my deal. Independent study demonstrated the Level Sleep mattress delivers a whopping 60% more satisfying sleep to owners

NATURE’S SLEEP MATTRESS

A gel and memory foam hybrid mattress that offers a medium to medium firm level of support. 14” finished height, does not offer a trial period. 20 year warranty, $2900 for a queen. Top of the line, with superior ingredients. Marc’s comments: Reviewers say that it shuts down tossing and turning. And that’s a tough one. A tad pricy, but owners swear by the top notch design and manufacturing..long lifespan, too.

NUVANNA MATTRESS

A gel and memory foam hybrid mattress that offers a medium to medium firm level of cradling support. Excellent outer covering. 10” finished height, 100 night trial, 10 year warranty, $765 for a queen. Priced right for utilizing the materials they offer. Free shipping. Marc’s comments: Customers love the efficient service and amazing massage like feel of this bed. One reviewer claims “it saved my marriage”. Hell, now that’s a review…

THE AVOCADO ECO-ORGANIC MATTRESS: CHEMICAL FREE SLEEP

Probably the cleanest, greenest, and safest bed you could buy. Made using only the finest natural and organic materials, including GOLS organic certified latex from tree-tapped sources, 100% GOTS organic certified wool and 100% GOTS organic certified cotton. To you, that means no-off gassing, or chemical textiles. Made in California in their own factories, a purely American company. The latex used is imported from India, collected by hand, and is the silkiest and smoothest botanical latex available.

LATEX FOR LESS: NO SYNTHETIC ANYTHING-REVERSIBLE, SO TWO BEDS IN ONE!

Pure botanical latex, GOTS certified, uses 100% natural cotton cover, 100% natural wool fire barrier, all at a reasonable price. The mattress is reversible offering two firmness options. Overall thickness is 9”, you’ll get a 120 night in home trial, a 20 year factory warranty, and their bed is completely made in the USA. Marc’s comments: They focus on delivering top drawer latex at controlled pricing. Flippable, so two beds in one. Good call on this bed-no frills, but super low pricing option.